Well... after many years adding to my 1/12th "to do" pile... I`m finally off and running. First one off the blocks is the JPS Lotus 72D.

I thought you might like to see my first efforts with my new mini lathe. At 49, my eyesight isn`t what it used to be, and the camera is very cruel... but hopefully my technique will improve in the months to come.

The "velocity stacks" and fuel induction system are the first thing I`m working on, so here goes with a little taster...

Aluminium stock faced and turned to 7.5mm dia.

End drilling with 3.5mm bit... after roughly turning to shape

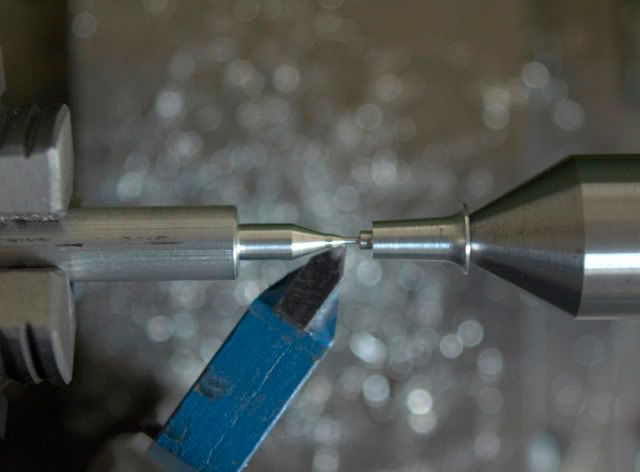

Using a specially ground/shaped tool for the final shaping

Inside drilled and sanded to shape... not perfect but won`t be seen anyway!

Parting off... the lathe work is now finished

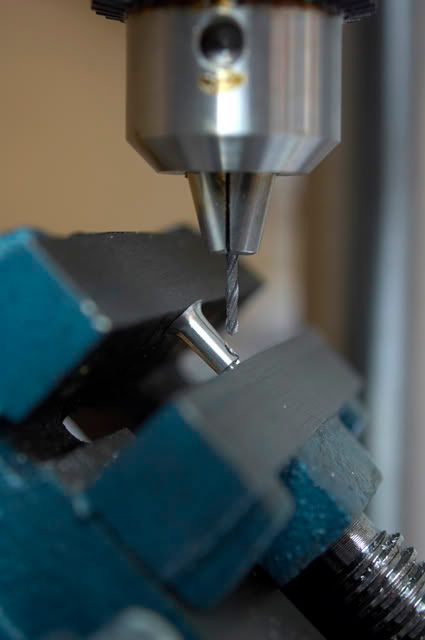

Into the drill press for an accurate 45 degree cut

... and a test fit onto the 1.8mm dia fuel inlet pipe

Test assembly of outer and inner pipes, locknut and... errm... modified kit part !! Well... I know my limitations

A collection of "work in progress"

One complete kit of parts, ready for painting and assembly... yahoooooo !

Test fit with a little blu-tak

The brass nut will be positioned properly on final assembly... promise !!

O.K.... I know what you`re all thinking. Why not just buy it all??? For sure... the stuff that`s out there at the moment is WAY beyond my capabilities, and the guys who sell their stuff have my undying admiration. BUT... I just have an insane desire to create, with my own hands, a DFV that is a real peice of "jewellery"... and who cares if I`m wearing rose tinted spectacles

Just for info... the inner sleeve and nut will be Alclad Jet Exhaust, and the remaining kit part Chrome Silver... the rest will be polished up and left as is.

Hope someone gets a little inspired to try this out... you`ll need a lathe, some tools... and endless cups of tea !!!

Cheers,

Howie

P.S. The more I look at that kit part... the more I want to make my own